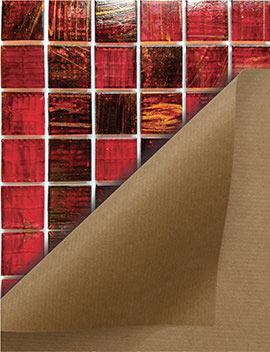

“Papered”

FMP (Face Mounted on Paper)

FMP (Face Mounted on Paper)

Papering is the conventional method used for assembling of mosaics. Under this method

paper is glued on the face of the mosaics (FMP). This is one of the universal ways of assembling mosaics into sheet.

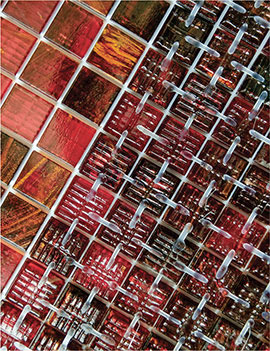

“LinkTec”

BML (Back Mounted on Link)

BML (Back Mounted on Link)

‘LinkTec’ is the state-of-the-art innovative technology for assembling of mosaics through Robot. Underthis method

polyurethane links are created at the back of the mosaics (BML) for assembling them into sheet.

- Advantages of “LinkTec” :

- Enables better intactness

- Easy and Faster installation

- Excellent finishing

- Water Resistant

- Weather Resistant

APPLICATION Surfaces

PALLADIO glass mosaic, being small in size, can be installed on curved surfaces as well. “Surfaces” where

PALLADIO can be applied are listed below :-

In case of artistic design, it is not advisable to use in submerged and floor areas. (*)

Light Residential: Floor coverings in areas that are walked on essentially with soft soled footwear or bare feet without scratching dirt.

(e.g. Residential Bathrooms & Bedrooms without direct access from outside)

(e.g. Residential Bathrooms & Bedrooms without direct access from outside)

Residential: Floor coverings in areas that are walked on by soft soled or normal footwear with at the most occasional small amounts

of scratching dirt.

(e.g. Rooms in the living areas of homes but with the exception of Kitchens, Entrances and other rooms which may have a lot of traffic)

(e.g. Rooms in the living areas of homes but with the exception of Kitchens, Entrances and other rooms which may have a lot of traffic)

Heavy Residential: Floor coverings in areas that are walked on with normal footwear more often with small amounts of scratching dirt.

(e.g. Residential Kitchens, Halls, Corridors, Balconies, Loggias and Terraces)

(e.g. Residential Kitchens, Halls, Corridors, Balconies, Loggias and Terraces)

Light Commercial: Floor coverings in areas that are walked on by regular traffic with some scratching dirt.

(e.g. Entrances, Commercial Kitchens, Hotel, Exhibition and Sale Rooms)

(e.g. Entrances, Commercial Kitchens, Hotel, Exhibition and Sale Rooms)

Heavy Commercial: Floor coverings in areas that are subject to severe pedestrian traffic over sustained periods with

some scratching dirt.

(e.g. Public areas such as Shopping malls, Airport concourses, Hotel Foyers, Public Walkways and Industrial Applications)

(e.g. Public areas such as Shopping malls, Airport concourses, Hotel Foyers, Public Walkways and Industrial Applications)

Glass Mosaic APPLICATIONS

Limited by our Imagination

PALLADIO glass mosaic is suitable for “interior” as well as “exterior” applications.

These applications can be in any “Sector” at many “places”, be it private or public, as listed below :-

Commercial :

- Manufacturing Plant

- Office

- Show Room

- Warehouse

Government :

- Court

- Defence

- Post Office

- RTO

Public Place :

- Airport

- Bus Station

- Metro Station

- Port

- Railway Station

- Shopping Mall

Educational :

- College

- Institute

- School

Hospitality :

- Club

- Hotel

- Resort

- Restaurant

Religious :

- Church

- Gurudwara

- Mosque

- Temple

Entertainment :

- Gym

- Multiplex

- Spa

- Theme Park

- Water Park

Medical :

- Clinic

- Diagnosis Centre

- Hospital

- Pathology

- Physiotherapy Centre

Residential :

- Apartment / Condominium

- Bungalow / Villa

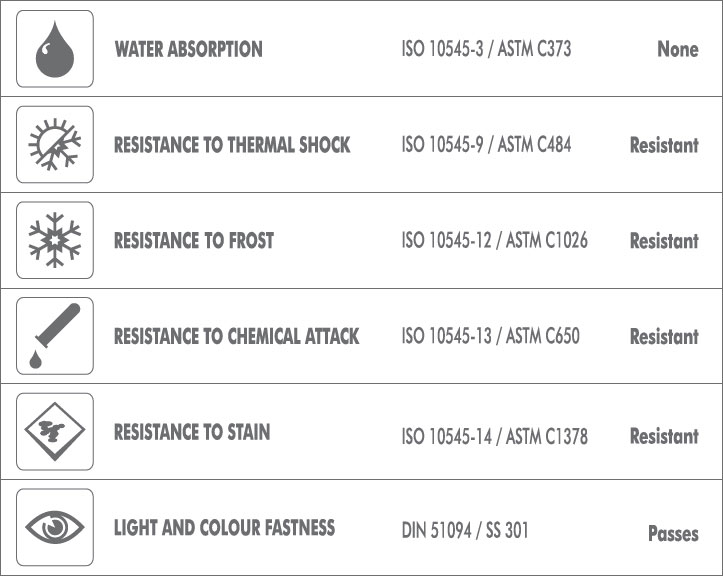

TEST Data

Manufactured as per International Standards

"PALLADIO" Glass Mosaic is manufactured using Fusion Technology and meets the specifications as per International Standards applicable for "Mounted Miniature Mosaic".

As per ANSI A137.2, mosaic having facial surface area or backside surface area ≤ 4.41 cm² and such that the longest side is not greater than 4.25 times the shortest side, fall under the category of "Miniature Mosaics".

The Technical data sheet is given here :-

As per ANSI A137.2, mosaic having facial surface area or backside surface area ≤ 4.41 cm² and such that the longest side is not greater than 4.25 times the shortest side, fall under the category of "Miniature Mosaics".

The Technical data sheet is given here :-

Design Installation

Since every installation is customized and unique, installation is done at site

based on the type of assembling:

For FMP (Face Mounted on Paper) assembled sheets :

(a) “Dry Laying Plan (Mirror View)” is used for the dry laying of

sheets to check the design before installation.

(b) “Installation Plan” is used to ensure proper positioning of the

sheets on the surface for proper installation.

For BML (Back Mounted on Link) assembled sheets :

“Installation Plan” is used for the dry laying of sheets to check the

design before installation, as well as for proper positioning of the sheets on

the surface for installation.

This will ensure accurate installation of the sheets to realise the design and to

avoid any mistake during installation.